Even more powerful is a digital twin’s ability to generate insights into how certain events might affect a company’s business. By simulating and modeling impacts and potential responses, a digital twin can suggest the best courses of action for the company to take. This is a huge bonus for a company during times of great uncertainty and can help leaders make much more informed decisions about how to proceed. So, for example, if a trading border shuts down, or if a plant is closed or if a line breaks down, the company will be able to pivot and adjust the supply chain because it’s able to quickly model alternative scenarios about where to produce, how and where to ship, and even where to redirect in-transit shipments.

One automotive company used a digital twin to help predict the financial health and viability of its tier 1 and tier 2 suppliers. This was vital, considering the just-in-time nature of the auto industry. If just one piece doesn’t make it to the factory, the company won’t be able to make the car. Modeling the health of the supply base enabled the company to identify a handful of suppliers that were under financial duress, and then make targeted interventions to improve their operational performance and profitability, consequently, reducing supply risks to the original equipment manufacturer (OEM).

Good processes all run on good data

Good, accurate data is a critical element of a digital twin’s effectiveness. If, for example, the order multiple for packaging materials is wrong, someone needs to manually change this every time an order is placed. Couldn’t the buyer avoid this by simply changing the master data for the order? They could do this, but for various reasons, doing so never quite makes it to the top of their priority list. So the practice can go on for months or even years.

Such master data errors can be found across a manufacturer’s operations, causing processes to bog down. In some cases, a manufacturer may have multiple entries for the same supplier and not know it. There may be a single typo in one of the addresses, or slight variations of the supplier’s name, or a headquarters address in one entry and a subsidiary address in another. If the manufacturer wants to analyze the amount it buys from that supplier, it has to de-duplicate all of those records so that it can get an accurate picture of total spend, which is an important tool in negotiating more favorable pricing terms.

Another example is lead time. There's often a lot of variability in delivery lead times, which isn’t surprising given it's a complicated process. But more often than not, we find that the system parameter settings for lead times are unduly generous or just plain wrong. If someone knows the settings aren’t accurate but doesn't fix them, he typically compensates by adjusting on the fly, which can only exacerbate the problem.

These and other situations are good examples of why manufacturers need a way to clean up their data on a regular, ongoing basis. The right analytics and machine learning can actually automatically identify these anomalies, suggest corrections and even (within rules) automatically correct master data. This kind of self-correcting or self-healing capability can be applied to nearly every type of day-to-day supply chain data, and can be part of an effective digital twin or operate on its own. In any way, it enables manufacturers to continually and automatically fine-tune their processes.

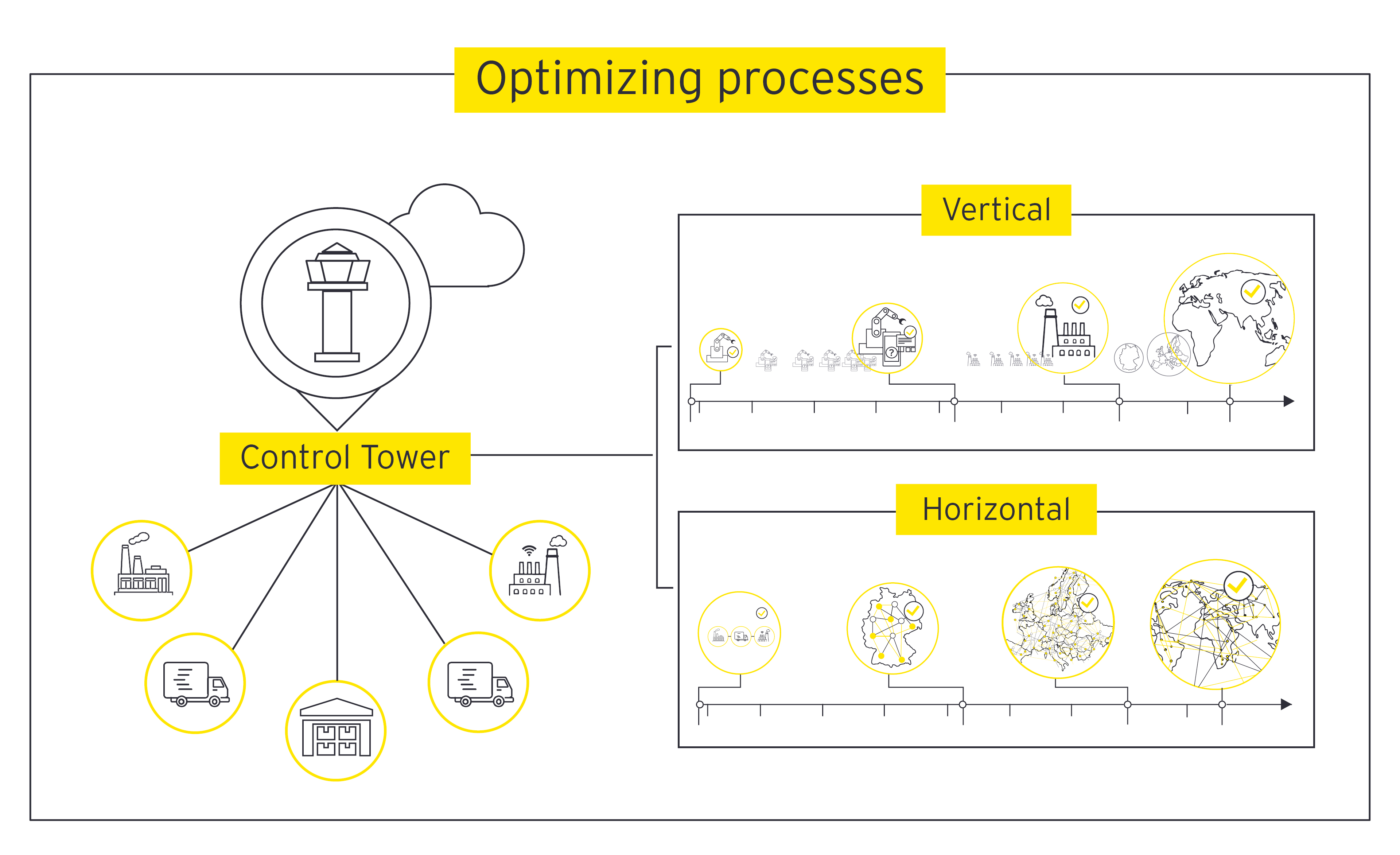

Microsoft technologies play a key role in optimizing processes

When considering digital twins, people may often picture actual 3D models — for instance, one of a jet engine that replicates how the engine behaves in the physical world. But when applied to the end-to-end supply chain, digital twins are more likely to be intuitive, easy-to-use dashboards. In either case, digital twins could in theory be fully automated — continually monitoring how a process is running and, on their own, make adjustments or take other actions to maintain optimal performance. In practice, that’s still a long way away for many industries and may never make sense for some. More often, there’s a symbiotic relationship between systems and humans. Automation and artificial intelligence (AI) may come up with recommendations, perhaps even test and run through the most likely alternative scenarios. But humans are still needed to review the options, perhaps refine them with the latest information that may not have been available earlier and make a final decision on the course of action.

While digital twins were on the cutting edge of innovation a decade ago, they’re increasingly becoming more mainstream and feasible for a wide range of manufacturers thanks to advancements in technology. In particular, a variety of technologies are putting digital twins well within reach of most manufacturers and are the foundation of the digital twin capabilities within solutions, such as EY Smart Factory.

Such technologies, like those powered by Microsoft Azure, start by helping manufacturers address one of their biggest, most enduring pain points: gaining good end-to-end supply chain visibility. This is accomplished by pooling data in a Data Lake from disparate supply chain systems — including information generated via internet of things (IoT) sensors embedded in equipment and other assets — as well as data on external factors, such as weather, traffic and newsfeeds. Aggregated data is then cleansed for access by a digital twin, which delivers insights generated from that data via a platform such as the Microsoft Power BI dashboard. Scenario modeling and recommendations are handled by technologies such as Microsoft Azure Cognitive Services, a family of AI services and cognitive application programing interfaces (APIs) that enables manufacturers to quickly and easily build intelligent apps that can drive more accurate and informed decision-making.

“Cloud-powered tools are a boon for optimization,” says Neal Meldrum, Business Strategy Manager at Microsoft. “They can optimize factory operations by: equipping people with the data and tools they need to identify areas of waste; improving cycle times for manufacturing operations; making automation processes faster and easier; maintaining equipment more efficiently by accurately predicting maintenance needs; dynamically realigning production to meet changing demands; and increasing turn-times for inventory across the value chain — all while reducing energy consumption.”