How can you use technology to turn trash to treasure?

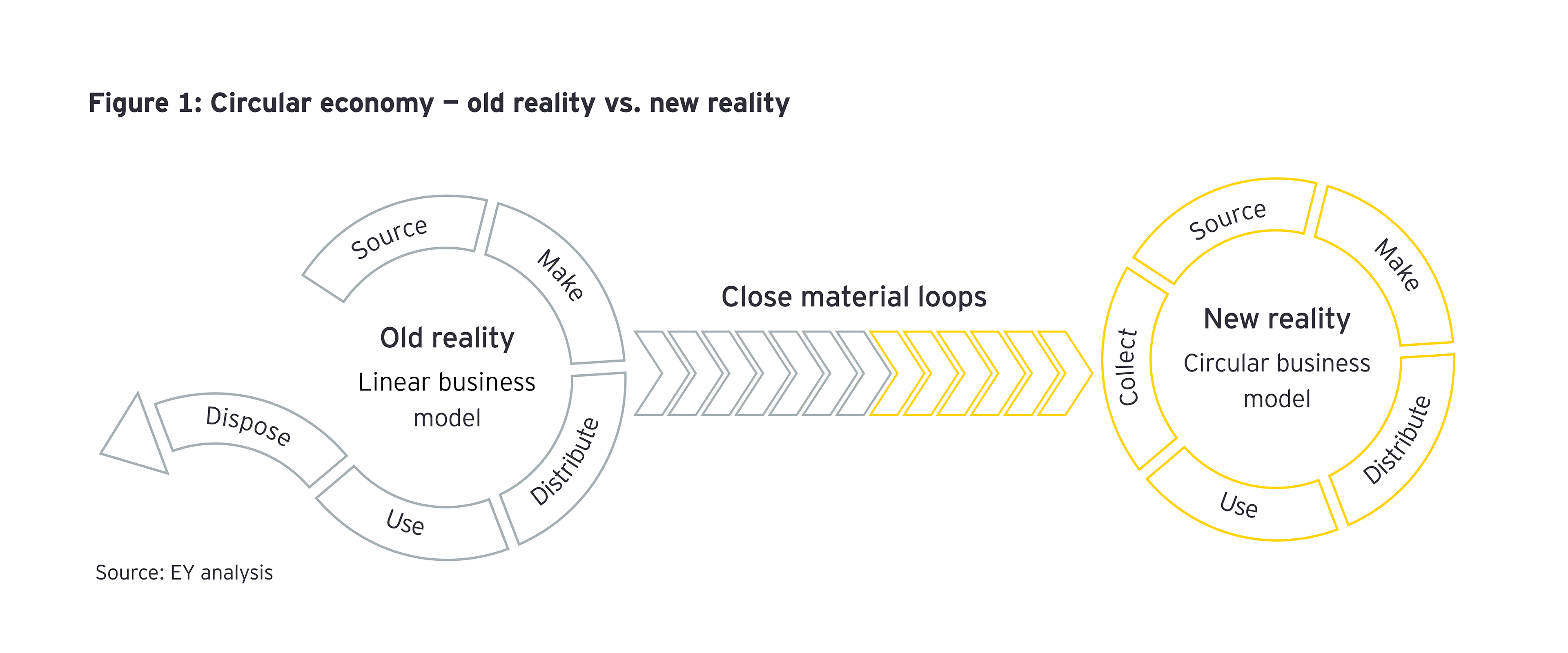

Collect raw materials, manufacture them into a product, sell the finished good and discard it after a single use. This is a linear business model. However, this model is quickly being tossed out for a new system — the circular economy. The principle behind this sustainable production model is to keep raw materials and finished goods in circulation for as long as possible to further extend product shelf-life and avoid filling landfills with excess waste. In addition to helping the environment, circular economies minimize resource use (reduce), maximize the use of products and by-products (reuse), and reuse raw materials (recycle) all while maintaining high-quality products use after use.

A 2022 Ernst & Young LLP (EY) report validated that the circular economy is gaining traction — with 72% of the cross-industry executives surveyed stating they already have or intend to execute plans involving circular economy strategies. However, research also shows that many of these companies feel they are lacking the visibility, technology and comprehensive programs required to accurately measure their progress in this area. With regulatory and customer pressures mounting, it is imperative businesses quantify their progress and deliver on their sustainability commitments.

The good news is manufacturers across energy, chemicals and other industries can play a significant role in the sustainability of products by ensuring their supply chain ecosystems are backed by circular behaviors. One multinational plastics, chemical and refining company, is exploring how digital technologies can help fully trace and track circular content throughout its manufacturing process. The technology will also quickly and accurately calculate the percent of circularity to obtain International Sustainability and Carbon Certification (ISCC).

Manual and cumbersome ways of determining circularity can introduce errors not only in the calculations themselves but also in the auditability and backtracking of the circular content in the finished product. These inaccuracies, in return, can introduce mistakes with onsite audits and miscalculations in buyer certifications. Technology can help expedite the process of determining circularity while providing better accuracy.

Supported by a cross-functional EY team with deep experience in Microsoft Cloud and Power Platform, blockchain, chemical and Climate Change and Sustainability Services (CCaSS), this multinational plastics company worked to create a digital ledger that would capture the percent of circularity in its products and help meet its ambitious sustainability goals.

Calculating circular content requires sophisticated solutions

With the goal of blazing a new trail in sustainability and circularity, the EY team and the client took a future-back approach, envisioning the needs of customers, businesses and regulatory bodies. A design workshop was held to capture the product requirements and identify an ideal support system. The team selected a lean, customized, Microsoft-enabled solution to act as the circular content ledger, calculating and attributing circular content to finished products in a traceable and auditable fashion. Microsoft Power Platform and Logic Apps integrated with the clients existing enterprise resource planning (ERP) system, while the power platform served as the lightweight, quick-to-implement front-end system fulfilling user-driven functionalities.

There are various technologies that have a digital ledger for circularity. The cloud-based Microsoft Power Platform offers a customizable user interface, end-to-end supply chain traceability and integration with existing ERPs.

Using the Power Platform for rapid prototyping and agile development, allowed for quicker iterations with business users and timely feedback shortening the overall development timeline. In addition, the solution leveraged the Power Platform and Azure infrastructure to scale as the client rolled out the solution around the globe.

“There are various technologies that have a digital ledger for circularity,” notes Erik Funfar, EY Americas Technology Leader for Sustainability, Ernst & Young LLP. “The cloud-based Microsoft Power Platform offers a customizable user interface, end-to-end supply chain traceability and integration with existing ERPs.”

By following the entire manufacturing process, the new automated certification validation system can generate legitimized calculations and recordings of the client’s positive environmental impacts. In addition, the sustainability certification presents solid evidence of recycled feedstock thereby helping this multinational plastics company further meet its sustainability goals.

Innovative technology sets the foundation for tokenization

The EY team provided the client with an innovative solution yielding a sustainability certificate that verifies the circular content throughout the sourcing and distribution of its products. The information can then be shared with retailers and customers, so they can feel confident they are buying responsibly-sourced and sustainably constructed products. The development of this certificate also reflects the client’s efforts to reduce its carbon footprint and be less reliant on fossil fuels.

The new certification validation system is expected to save

5,000hours of manual effort.

The new automated certification validation system was delivered in an impressive six months, two times faster than other solutions. Additionally, with a bold goal of selling millions of metric unit tons of circular-certified plastic products by 2030, the new system is expected to account for a significant percentage of sales of circular products. Finally, the new system is expected to save approximately 5,000 hours of manual effort.

The new automated certification validation system can generate legitimized calculations of the client’s positive environmental impacts.

For the client to deliver on their sustainability goals, they recently announced a new organizational structure including a circular and low-carbon solutions business segment. And in late 2022, the client developed a prototype for a digital product passport that would benefit the entire supply chain — from downstream customers to upstream suppliers. The new digital passport gathers circularity data, including carbon emissions, across the entire supply chain and makes the information available to all stakeholders, including consumers. And while this is a great accelerator, the client’s ultimate step will be to tokenize the certificate on a public blockchain helping other supply chain partners benefit from the data as well.

Just like this client, many manufacturers have aggressive targets for certified polymers. And according to the Ellen MacArthur Foundation, 45% of global emissions can be eliminated by rethinking manufacturing, distribution and production. By taking steps to measure and track circular content, companies can make positive strides toward a circular economy.

The team

Contact us

Like what you’ve seen? Get in touch to learn more.