For many manufacturing companies, the potential of artificial intelligence (AI) is easier to envision than the reality, and the journey between current and future states has begun only in earnest. The transformative power of the technology remains on the horizon. Yet, a pioneering EY and Microsoft study shows why there’s no time like the present to start capitalizing on AI.

The survey of 86 manufacturing companies across Europe has implications for the sector across the world, revealing that 81% agree that AI has become more important for their business over the past 12 months, but just 10% say they have a detailed plan for it with initiatives and defined responsibilities. Meanwhile, 16% say that they are still developing and implementing AI on an ad hoc basis. Just 12% have managed to scale AI company-wide, and these leaders have been on their journeys for over five years, on average, reporting lower costs, sharper decision-making and greater customer engagement.

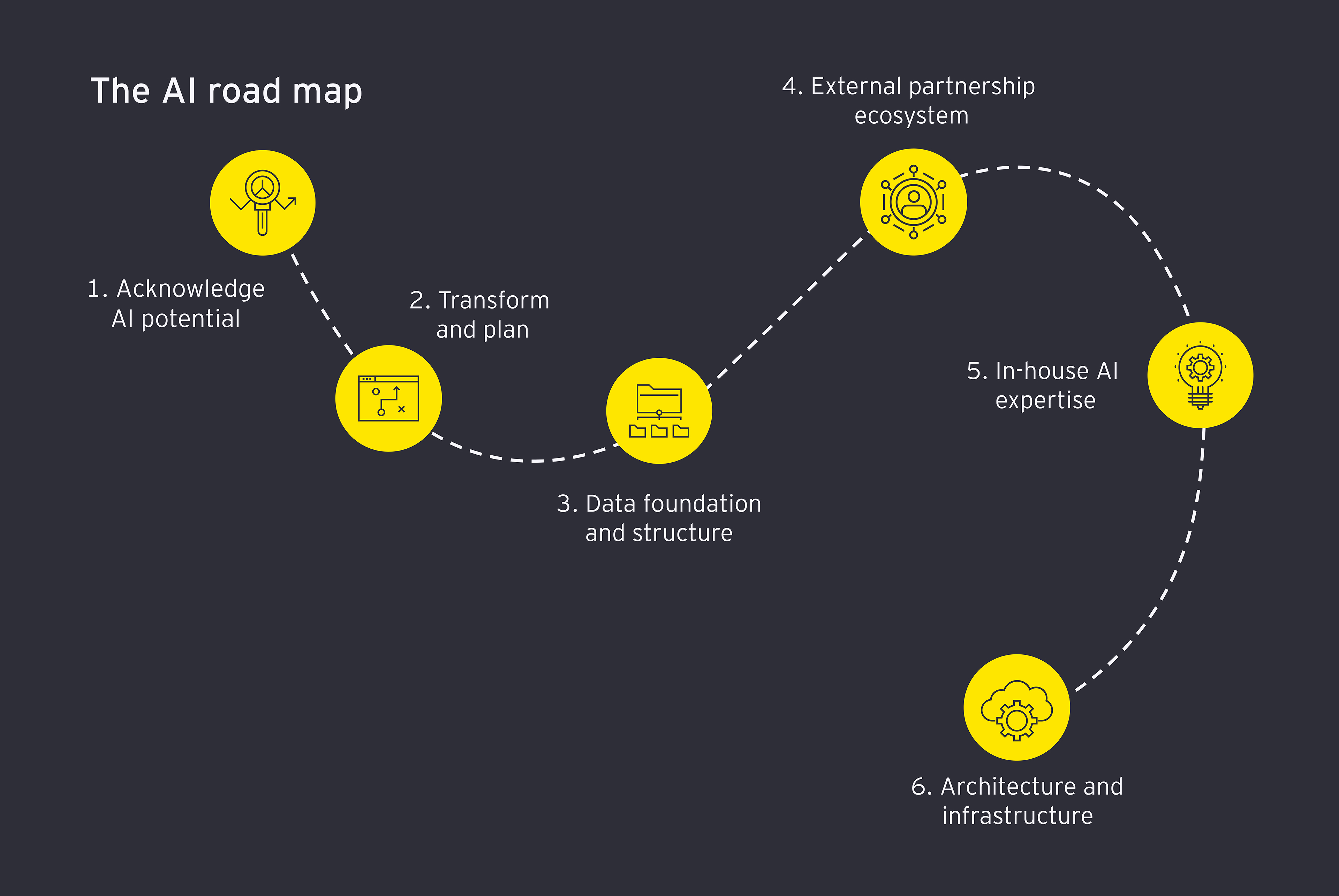

Becoming a leader who integrates AI within their business is more than installing new software and reaping the rewards. It requires time and careful planning — but the payoffs are substantial. Our survey (described in more detail in the full report) shows where the opportunities lie and how manufacturers can replicate some of the leading practices.

Opportunities and hurdles

Going back to 2014, manufacturing companies were involved in just five M&A deals focusing on AI, according to EY Embryonic. That number shot up to 59 in 2019, totaling 179 transactions over that time period, with a compounded annual growth rate (CAGR) of 64% and a total transaction value of €1.4 billion.

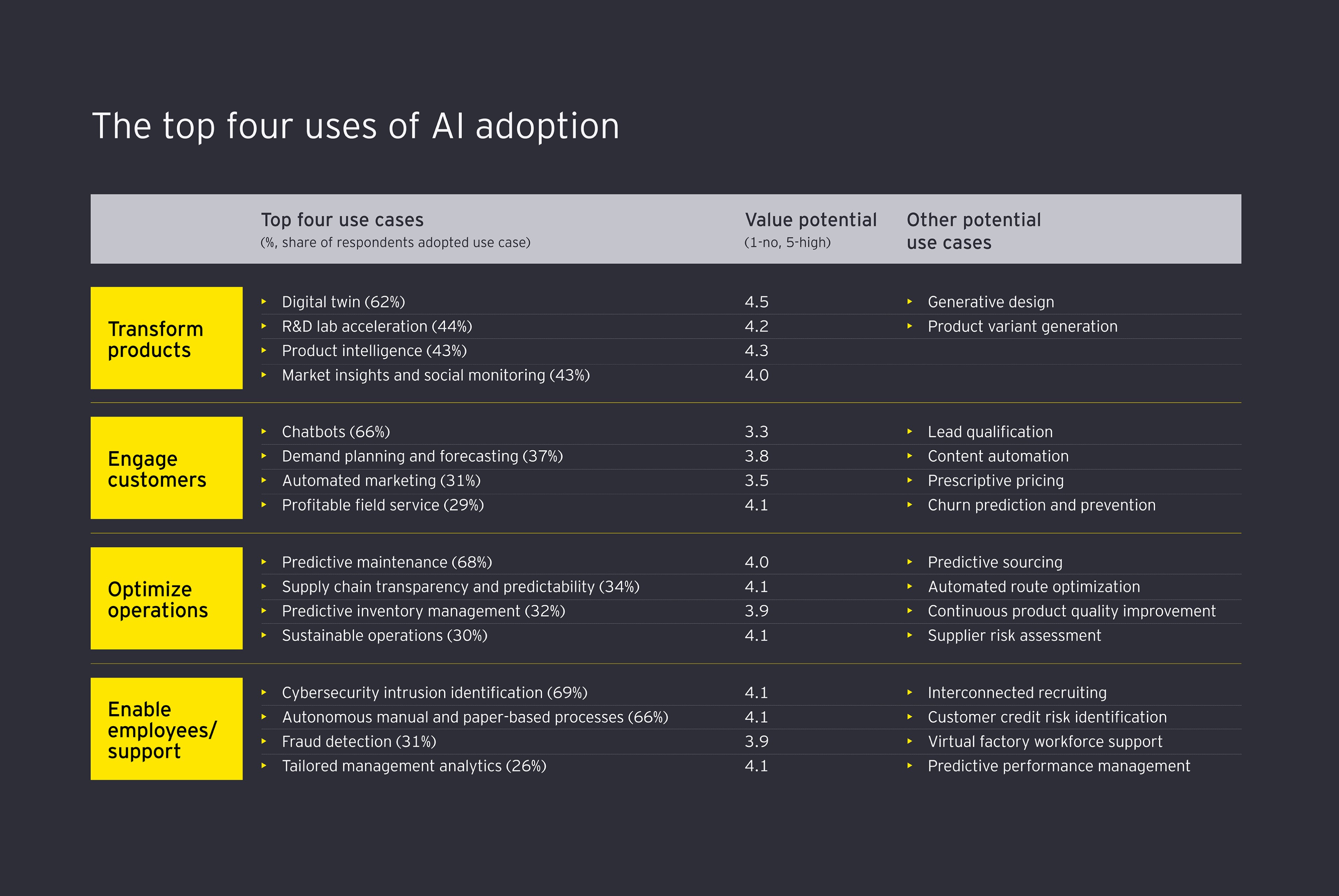

It’s easy to see why manufacturers are enthusiastic about AI. In factories, smart sensors, the internet of things and AI enable predictive maintenance — used by 68% of survey respondents — to save costs and extend the lifespan of important assets. Then there are digital twins, which are virtual replicas of a product, process or piece of equipment to use in simulations. In the survey, 62% say they have adopted digital twins — for example, in making supply chains more resilient. AI can play a role at the other side of the value chain as well by enabling chatbots — used by 66% of survey respondents — to respond to inquiries quickly through text analysis, and cybersecurity intrusion identification was a popular response as well (69%).

Other use cases are more nascent but also powerful — for instance, AI can help forecast customer demand (37%) and manage inventory (32%) for seamless fulfillment. Analytics also can drive better decision-making and more effective utilization of labor, and AI visual analytics can be used in maintenance for faster inspections and verifications.