The time of Operational Technology connectivity and convergence

The simple definition of Industry 4.0, often known as the fourth industrial revolution, is the use of digital technologies during an industrial process to produce the output with higher quality at a lower cost. Although manufacturing process automation has been a result of advancements in electronics, information (IT) and operational technologies (OT) for the last 70 years, it is only more recent improvements in digital technologies that are starting to broaden the area of disruption. To realize significant cost savings, greater productivity but also new revenue and business model opportunities industrial organizations must increase connectivity, democratize data and automate their business processes while remaining resilient to cybersecurity threats which impacts the industry.

To achieve the above benefits of connected, smart and resilient manufacturing, organizations integrate not only the IT and OT management technologies but also the underlying OT and Cyber organizations and processes. As of 2021, 9 out of 10 companies believe that digitization brings more opportunities than risk, while 97% of executives in the industrial area point out that the biggest challenge to technology adoption is an integration of new and legacy technologies from different eras (57% identified it as a major challenge).

Building OT Digital Plant Foundation for the future

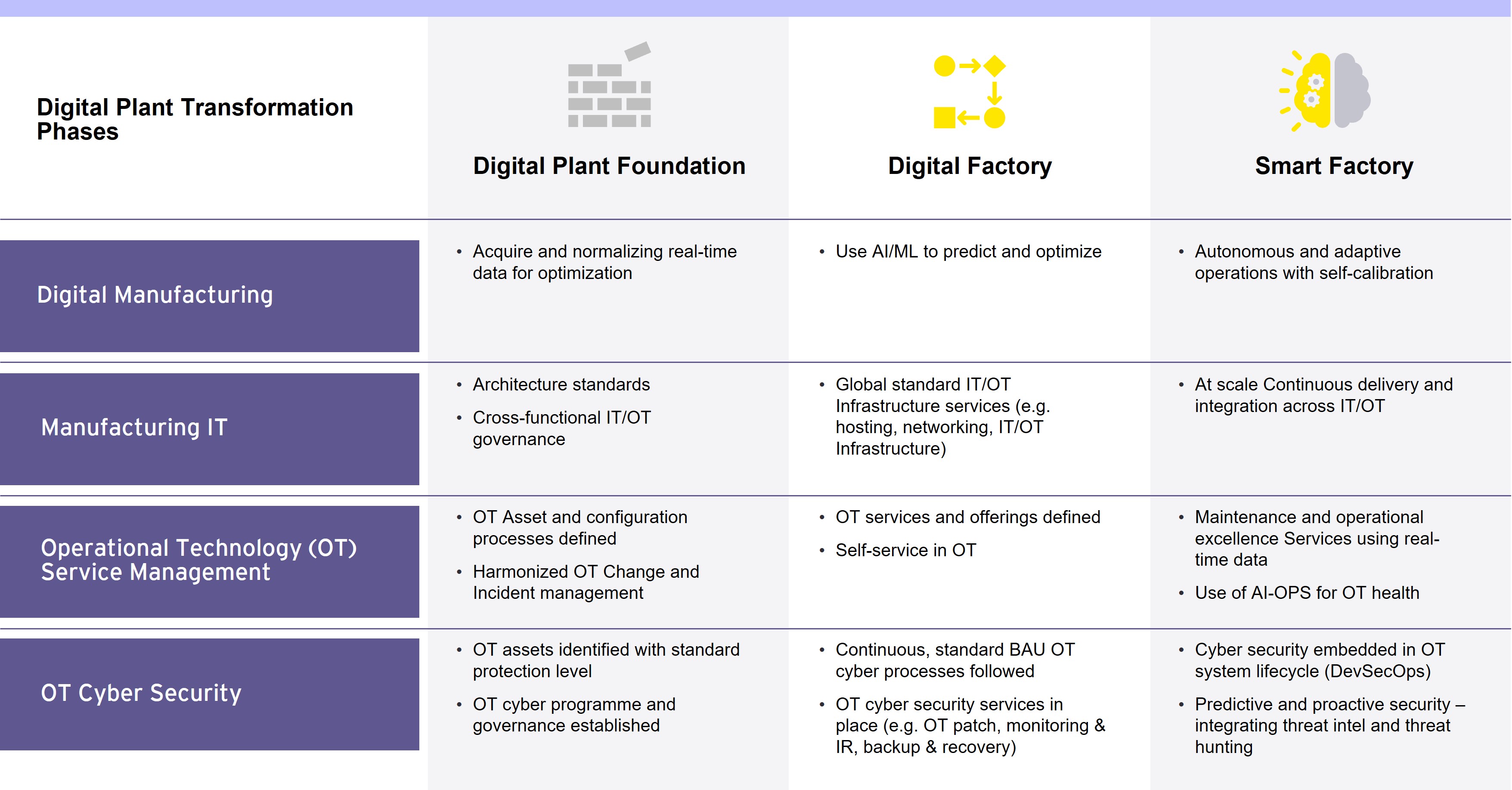

After the initial period of extended IT/OT cyber security remediation programmes on one hand (bringing IT, OT and Cyber people and processes closer together) and advanced proofs of concepts related to digital shop floor operations on the other - we observe now a more methodical approach, focused on building Digital Plant Foundation. The Digital Plant Foundation is critical before moving to Digital Factory stage where the data is used in a real-time to support decisions and predict actions, and further – to Smart Factory where high-quality data and automation allows for autonomous and adaptive operations which self-optimize equipment performance, product quality or energy consumption.

Properly addressed Digital Plant Foundation introduces new tools and techniques in which integrated IT/OT technologies are being managed and protected as:

OT projects are more often delivered by Agile Manufacturing Technology Teams that work hand-in-hand with IT, Engineering and Security teams. OT applications and OT infrastructure need a more agile approach throughout its lifecycle (delivery, lifecycle management, security risk/compliance and operations).

The scale and speed of change as well as amount of threats and vulnerabilities to be managed in a typical OT environment – makes it difficult to be handled manually. Orchestration and automation of discovery, change and security processes allows to keep up with the amount of IT/OT cyber risks and allows to focus on what matters most to the operational teams.

The dependency between IT and OT management domain increases and teams integrate and converge in more and more organizations. So should the processes responsible for management and maintenance of the underlying IT/OT infrastructure and applications. The journey of OT towards a Service-oriented model allows IT teams to speak with OT in the same language, and OT to have a better visibility of how IT can help them deliver their work.

To achieve Digital Plant Foundation organizations should understand what IT/OT assets they run in the field, what industrial process those asset support and who maintains them. As soon as they have these foundations established they can overlay it with value added information like state and condition of the asset, vulnerability information or proposed patches for cyber risk remediation. The same set of information can be used to harmonize, improve and even automate processes around OT service management (configuration, change, incident, request), OT cyber security and risk or even OT lifecycle and maintenance management.

Summary

The acceleration of digital transformation across manufacturing and utility organizations pushed for significant IT/OT convergence hence creating demand for new infrastructure and cyber security services across Operational Technology (OT) landscape. But in order to keep up with this business demand, providing good quality and secure OT services organizations need to ensure they have built solid digital plant foundations. These foundations should allow organizations to digitally transform with confidence and at speed even in times of high uncertainty and resource shortage. Only with properly addressed organizational, technical and operational foundations a true business value from Operational Technology can be unlocked and realized.