Chapter 1

Data is key

Value is leaking across the oil and gas value chain through inefficiency and failure to fully leverage data.

Companies generate huge amounts of data while exploring for, and producing, oil and gas. Despite cutting-edge technology below ground, above ground much of that data is currently recorded manually in multiple, disconnected paper records or spreadsheets. Various teams engaged in the upstream life cycle — from land and lease management and well planning, to production — work in silos and use different data management practices. As a result, employees spend a lot of time finding and validating data manually. This leads to delays and impacts critical decision-making.

And because upstream operations are highly complex, large-scale and capital-intensive, even small errors and inefficiencies cost millions of dollars and cause months of delays. For example:

- At many companies, rig schedules are reworked at least 75% of the time, primarily due to non-integrated data between production and land departments, and a lack of clarity on what a company owns and where.

- Companies sometimes inadvertently lose value from expiring leases due to unmet minimum drilling commitments.

- An oil and gas company, on average, faces nearly 27 days of unplanned downtime annually,1 amounting to losses of between US$38 million to US$88 million.

- A disconnected view of upstream operations makes it difficult to accurately estimate equipment and materials needed at an oil and gas field. As a result, companies tend to overbuy, resulting in billions of dollars of unneeded supplies tied up in inventories.

Chapter 2

Significant opportunities await

Oil and gas companies stand to gain more than US$145 million annually by integrating key upstream processes via common data models.

A digital, centralized data platform provides a holistic view across the value chain, and helps companies make better-informed decisions to unlock significant value. Customized access, automated calculations and real-time alerts enable employees to view actionable information and manage fields “by exception.”

Our estimates show that an oil and gas company could potentially unlock more than US$145 million of value annually by integrating its key processes across the upstream oil and gas value chain with a common data model. This is nearly 2% of the average income of an international oil company (US$8 billion in 2019). Additional benefits include a reduction in process times and changes in rig schedules, as well as less unplanned downtime. A breakout of the potential value to be realized is presented below.

Potential value creation from integrating upstream processes via a common data model

Source: GlobalData, company reports, EY analysis

Land and lease management

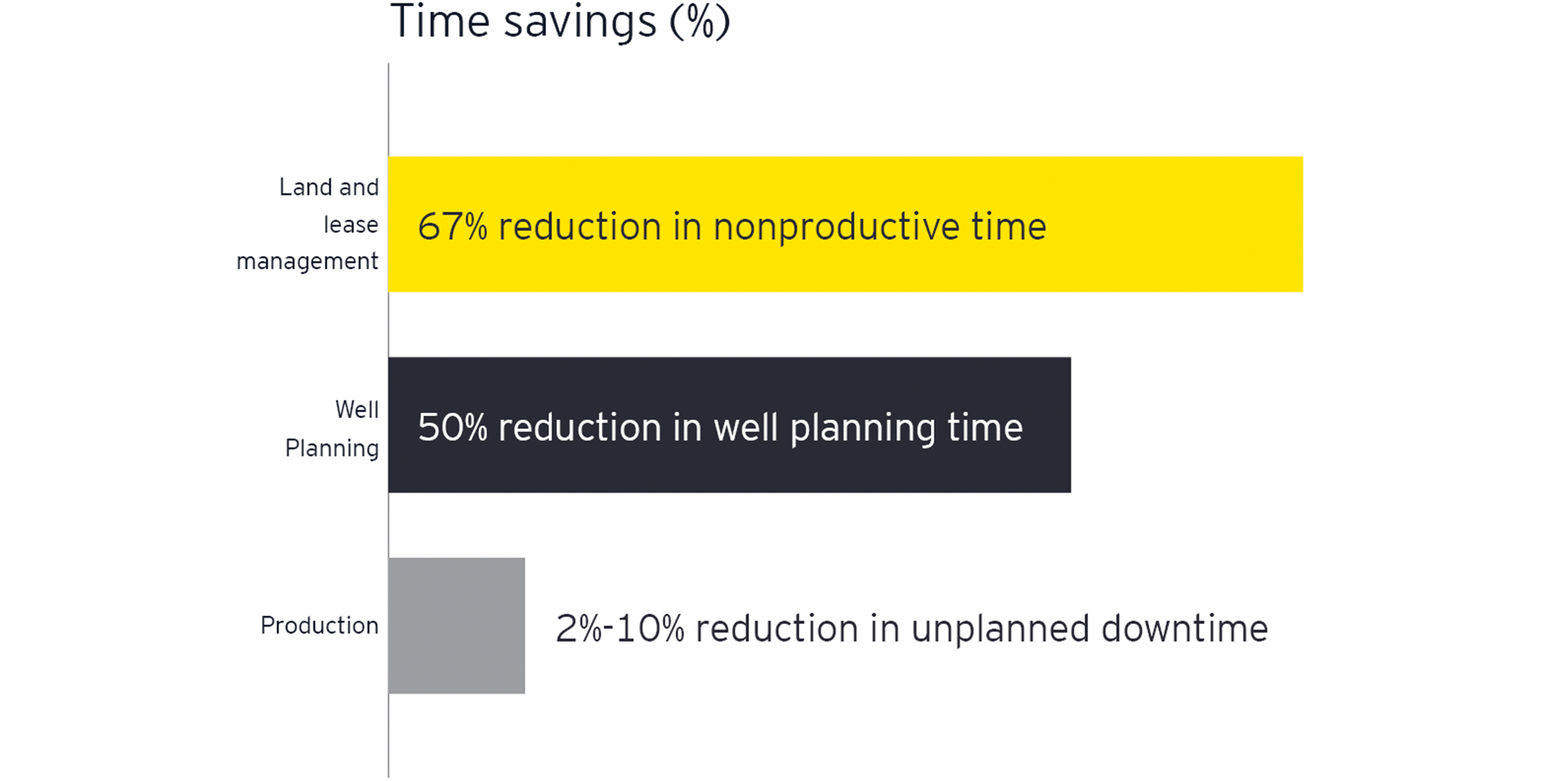

Data integration across upstream departments could reduce non-productive time due to changes in rig schedules from 75% currently to 25%. It could also enable landmen to recognize and progress acquisition opportunities in case partners go “non-consent” after drilling expenditure is authorized. Such acquisitions could increase revenues for an oil and gas company. Oil majors and leading North American independents drill an average of 275 wells a year, and up to 750 in some cases. Assuming a portfolio of 275 wells, we estimate additional revenues of US$17 million annually.

Well planning

It takes three well planning engineers as long as 12 months, on average, to design and plan a single well. Data integration across the well life cycle could streamline well planning, reduce process time by at least half and result in significant annual savings. The EY Digital Energy Enablement Platform (EY DEEP), for instance, delivered cost savings of US$60 million over the course of one year for one business unit at a large integrated oil and gas company.

Production

An oil and gas company operates or partners in nearly 4,000 producing wells, on average, while some IOCs are involved in more than 47,000 wells. Average annual opex per well is around US$1 million and could go up to US$18 million in some high-cost basins. Opex varies across geographies and resource types, ranging from US$2–US$3/boe in low-cost producers, such as the Middle East and Russia, to as high as US$21/boe in unconventional resources, such as heavy oil and oil sands in North America.2

Integrated and data-driven management of oil and gas production has the potential to reduce upstream opex by 10% to 30%. This translates into opex savings of US$0.1 million to US$5.0 million per well, or US$0.2/boe to US$6.3/boe. Similarly, unplanned downtime could be reduced by 2% to 10%, which could save an additional US$0.8 million to US$3.8 million annually.

Apart from cost benefits, additional revenues and time savings, oil and gas companies also reap intangible benefits, such as enriched jobs, smooth knowledge transfer and improved employee experience. Digitization of upstream business process flows could automate routine tasks and allow employees to spend time on strategic tasks that add value in the long run. For instance, engineers and landmen could spend less time hunting for data and cross-checking and updating it across spreadsheets. Instead of troubleshooting, they could spend more time in contingency planning. Operational awareness from experienced employees and historical project data could be preserved in a virtual format to enable smooth knowledge transfer and ensure continuity as staff retire or shift to new roles. Use of data-driven and digital technology could also make upstream jobs more attractive to younger hires as the industry faces competition from other sectors in hiring new talent.

Chapter 3

Capturing the value

How oil and gas companies can make the most of their investment in a digital, data-driven operation.

The current industry downturn and reduced capex could make it difficult for many companies to commit the necessary capital for digital transformation initiatives. Companies must take a long-term view on digitization, think of creative ways to offset the capital investment and ensure that maximum value is realized from their investments. The right choices made on the journey to an integrated, data-driven and digitally enabled upstream function can help companies make the most of their investment.

Buy vs. build

Companies pursuing digital initiatives often face a buy-or-build dilemma. Many large oil and gas companies may possess the ability and capital to develop a proprietary common data platform in house. However, they must evaluate if buying or co-creating solutions with a service provider could be quicker and more cost efficient. The latter could also allow a company to evaluate multiple options that are available in a relatively short period of time and run pilot tests before making large capital commitments.

Phased implementation and measuring value

Once the solution is finalized, companies looking to avoid large up-front payments could consider a phased implementation (e.g., at select business units) and scale up over time. Measuring value throughout this process is important. While companies consider estimated benefits when making investment decisions on digital initiatives, many fail to track the actual benefits realized after implementation and document lessons learned.

Integration and scalability

Solutions or applications that cover the complete field life cycle should be preferred over those that cover only specific departments (such as land management). Similarly, products with end-to-end functionalities, ranging from digitization of documents and data integration and reporting, to decision-making, should be the preference. Integration with the organization’s existing software applications (e.g., ERP) and scalability to match the company’s operational footprint will also help unlock synergies.

Customization

While upstream oil and gas processes are commoditized, some extent of customization is often required in digital platforms to meet the organization’s unique operational and reporting needs. Solutions that offer a fair amount of customization should be preferred over off-the-shelf ones that may solve only part of the problem and result in lower adoption.

Data sharing

When purchasing external solutions, companies must also ensure they have a clear view regarding who owns the data and how it is shared and used. They should choose vendors and service offerings based on their preferences or degree of comfort around sharing their data externally.

Cultural shift

Companies must go beyond simply coaching employees on new technologies and centralized data management practices and instil a shift in mindset away from working in silos to more shared and transparent ways of working.

Digital integration positions companies for success in a new market environment

Effectively integrating digital technology across oil and gas organizations will help deliver tangible results, reducing costs and improving efficiency throughout the oil and gas value chain. Companies that want to remain competitive throughout the energy transition and in a changing world can leverage their data to help improve productivity, streamline operations, accelerate decision-making and eliminate costly delays and errors.

Summary

The oil price crash, precipitated by the COVID-19 crisis, has exacerbated the pressure on oil and gas companies to cut costs and increase efficiency. Bringing people, processes, tools and data together through integrated technology can drive value across oil and gas. It is this type of holistic transformation that will help oil and gas companies navigate the energy transition.