How can industries collaborate to effectively tackle critical mineral shortages?

- Dismantle barriers to educate stakeholders. Many audiences fundamentally don’t understand the impact that minerals have on everyday life. To foster cross-industry collaboration, we need mining and government to invest and educate people, demystifying the industry and building awareness. At the industry level, we’re seeing initiatives like this take shape through Canadian mining associations. Now’s the time to double down and help amplify that messaging to bring stakeholders — new recruits, potential investors, local communities and others — on board.

- Address ESG issues strategically. Each of these sectors has a significant impact on the environment, spanning the end-to-end value chain. As they continue to progress and meet ESG targets, there must be greater reward from investors and capital markets, encouraging stakeholders to make decisions and allocate capital to alternative sources or models that are greener. Capturing the opportunity cannot be at the expense of the progress made on the ESG agenda.

- Create clear ownership. Miners will need relationship brokers operating at the heart of organizations and the industry itself. This piece is foundational. It applies across industries but has a particular significance for mining. Who will bring disparate players together? Who will rally conversations and action? Mining must prioritize collaboration alongside any other strategic business imperative to really make this work.

2. Mass electrification requires massive infrastructure investments.

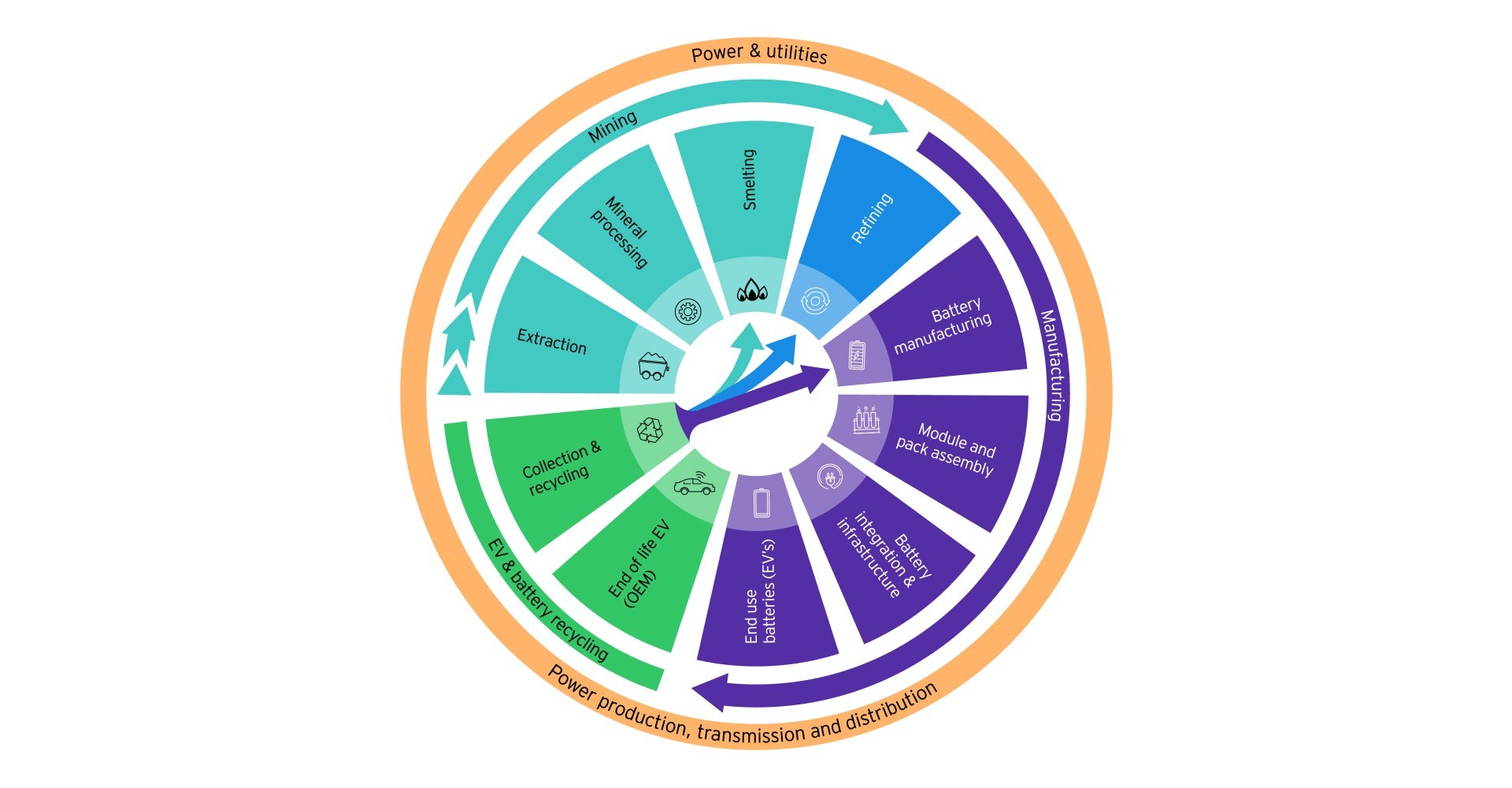

Upstream, downstream and consumer power needs are poised to change dramatically as EV adoption takes hold in Canada and beyond. High adoption scenarios that suggest 30% of all cars on Canadian roads should be EVs in the next seven years would require a significant national charging infrastructure. Looking beyond the charging stations themselves, that kind of undertaking also necessitates major expansions to everything from hydro poles to wires, transformers and more. And that’s all just to support the actual cars.

Electrification at scale would require a tremendous network of charging infrastructure. Right now, that represents a big gap in Canada. Even so, it’s not just the cars themselves that will require more power. Ramping up critical mineral extraction means building and extending power networks in new and sustainable ways to offset the uptick in carbon emissions as production grows. Building out additional capacity at automotive and manufacturing production sites — including automotive manufacturers — could necessitate similar growth of the power network. That’s to say nothing of the uptick in home-charging stations and private facilities, and the work that would entail.

What’s more, as we continue to retire coal plants and look for cleaner generation as part of the energy transition, load balancing will also become a critical challenge requiring strategic thought. That discussion should likely cover the use of intermittent wind and solar power, the short-term need for more hydro and natural gas generation — and a fulsome, longer-term dialogue about the role nuclear can or should ultimately play.

All of this comes at a time when utilities continue to be plagued by regulatory conflicts of interest between their core purpose - providing accessible and affordable energy — and the need to adapt, innovate and build for a very different future. Making good on EV uptake targets will also likely require broader regulatory and policy change. That’s critical to support the lightning-speed growth necessary if power and utilities giants are going to keep up with decarbonization and EV adoption in Canada. Anything less could widen existing geographic disparities.

Case in point: incentive and tax credit programs for EVs vary significantly from British Columbia to Ontario to Québec. Put that in the context of power and utilities, and it’s clear that the regulatory environment doesn’t really support the industry in thinking or innovating outside the box.

Utilities themselves are mandated to manage rate costs while delivering enough safe and reliable energy to meet current needs. That doesn’t leave much room to proactively adapt to what’s coming down the pike with EVs. What’s more, it begs the need for reaching across industry and sector lines to make progress quickly.

The oil and gas industry offers prime examples of massively collaborative approaches to fuel innovation. Companies are investing significant dollars to better understand the transition through their significant retail footprints. We’re already seeing big energy brands move into the power generation space with a focus on renewable energy: think solar and wind. As a sector overall, oil and gas companies are also converging around high-impact possibilities like hydrogen, carbon capture utilization and storage (CCUS) and natural gas — all necessary to support Canadian electrification.