Chapter 1

Digital twins in action

These virtual tools have a real-world impact that can improve bottom lines, providing the agility needed in a disruptive world.

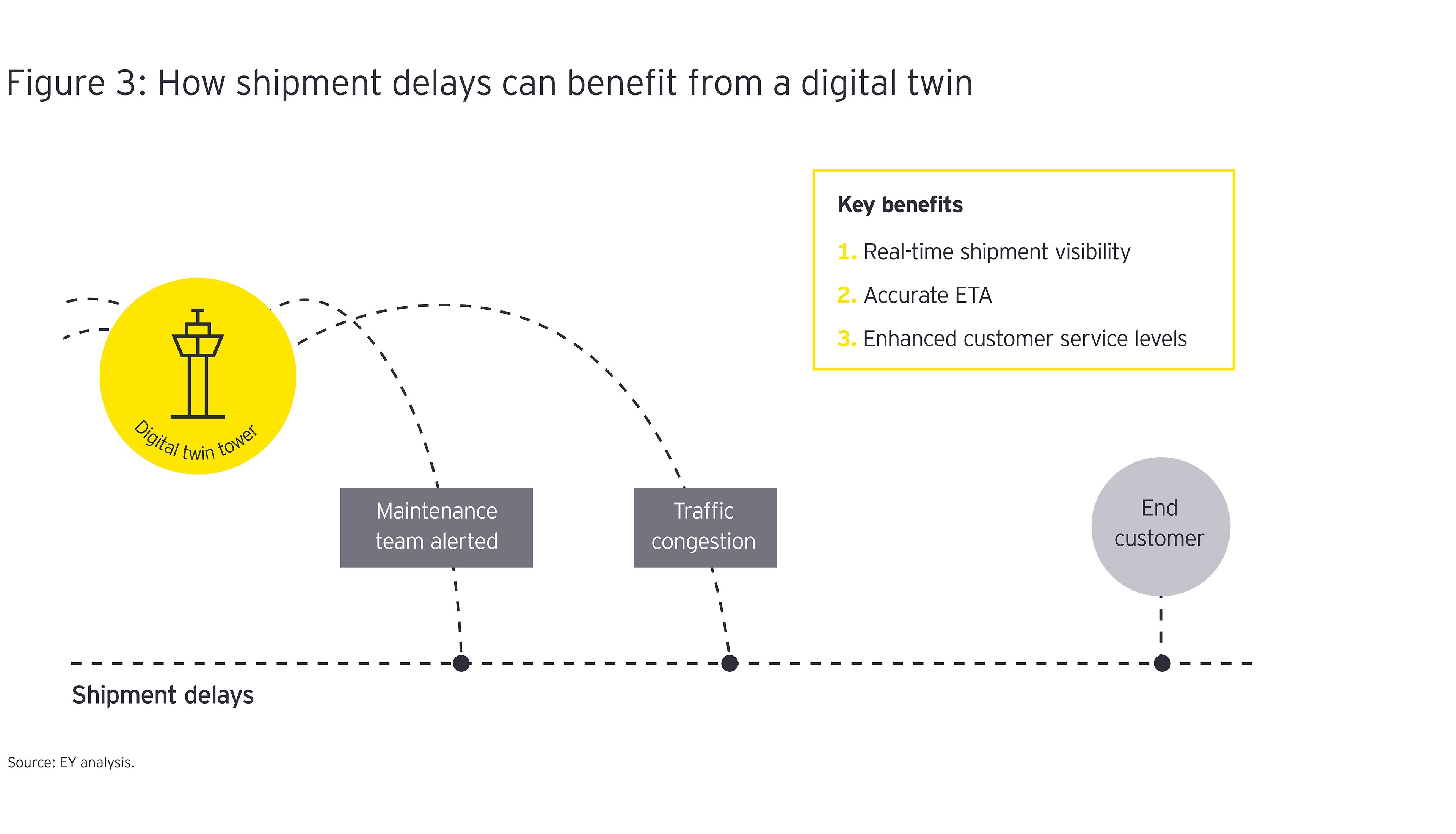

In practice, a control tower can detect shipment delays by examining signals from GPS devices and comparing expected and scheduled times of arrival (see Figure 3). Root cause analyses can be performed to not only suggest solutions but alternatives for other customer orders, such as shipping from another warehouse.

Similarly, in response to a crisis such as the pandemic, a control tower can use system thresholds on orders (like cancellations) to detect shifting demand patterns and even recommend changes to production levels of certain products as a result. During a natural disaster, IoT sensors on production equipment send a signal about unplanned shutdowns to control towers, which can then look for alternate product sources and then indicate when impacted customers should be informed.

A strategic twin can help inform long-term decisions by including simulation and optimization capabilities across the end-to-end supply chain. Imagine a situation where a future tariff change creates competitive pressures on your business model. How would you react? Traditional methods would necessitate significant manual effort, sacrificing time and often ceding the competitive advantage to competitors. A strategic digital twin can help identify and estimate the impact to your business in near real time.

In addition, it can help model alternatives and determine a network design that allows you to optimize across your chosen parameters. In the recent months since COVID-19, EY clients have also increasingly begun to explore long-term onshoring as a means of managing their operational resiliency. For those with physical supply chains, this increases the need to make decisions based on a multitude of factors – present and future demand patterns, operational and capital expenses, and service levels, among others.

A strategic digital twin allows companies to simulate these scenarios and enable more proactive and informed decision-making. In addition to these use cases, the applicability of strategic digital twins is vast. They can be used to solve for pressing needs, including modeling supply chain risk, and helping the business structurally minimize delivery times, among many others. In a time where agility is more important than ever, a strategic digital twin helps drive substantial value to the end-to-end supply chain.

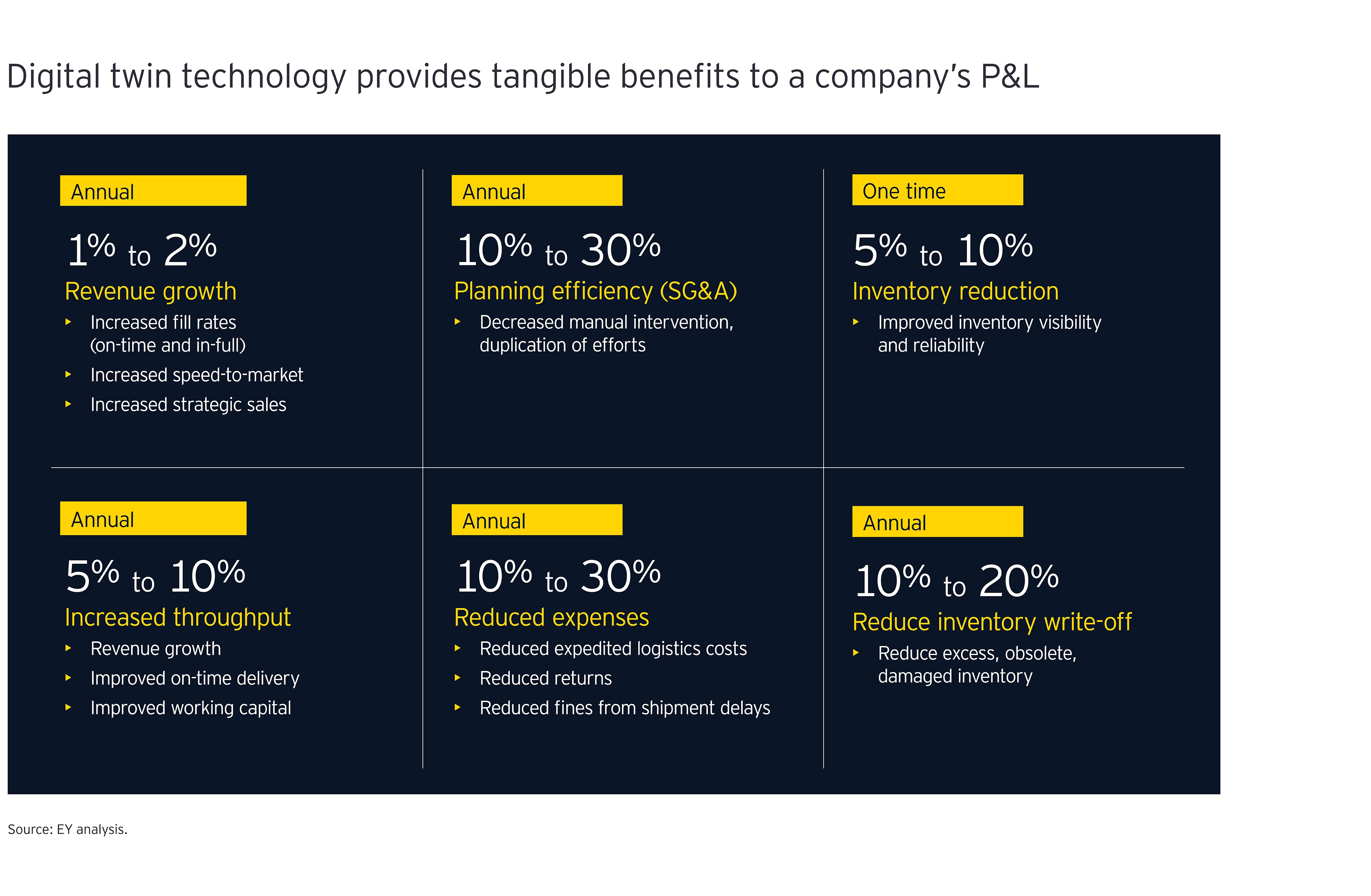

Experience from EY teams indicate that digital twins add agility and drive better decision-making that can provide a significant impact to a manufacturer’s bottom line.

How EY can help

Smart Factory

EY Smart Factory arms your shop floor with dynamic predictive data analytics, virtual reality and artificial intelligence to deliver unprecedented performance.

Read more

Chapter 2

Different considerations and road maps

A decade ago, digital twins would have been impossible. While they require integration and connectivity, holistic approaches can get the job done.

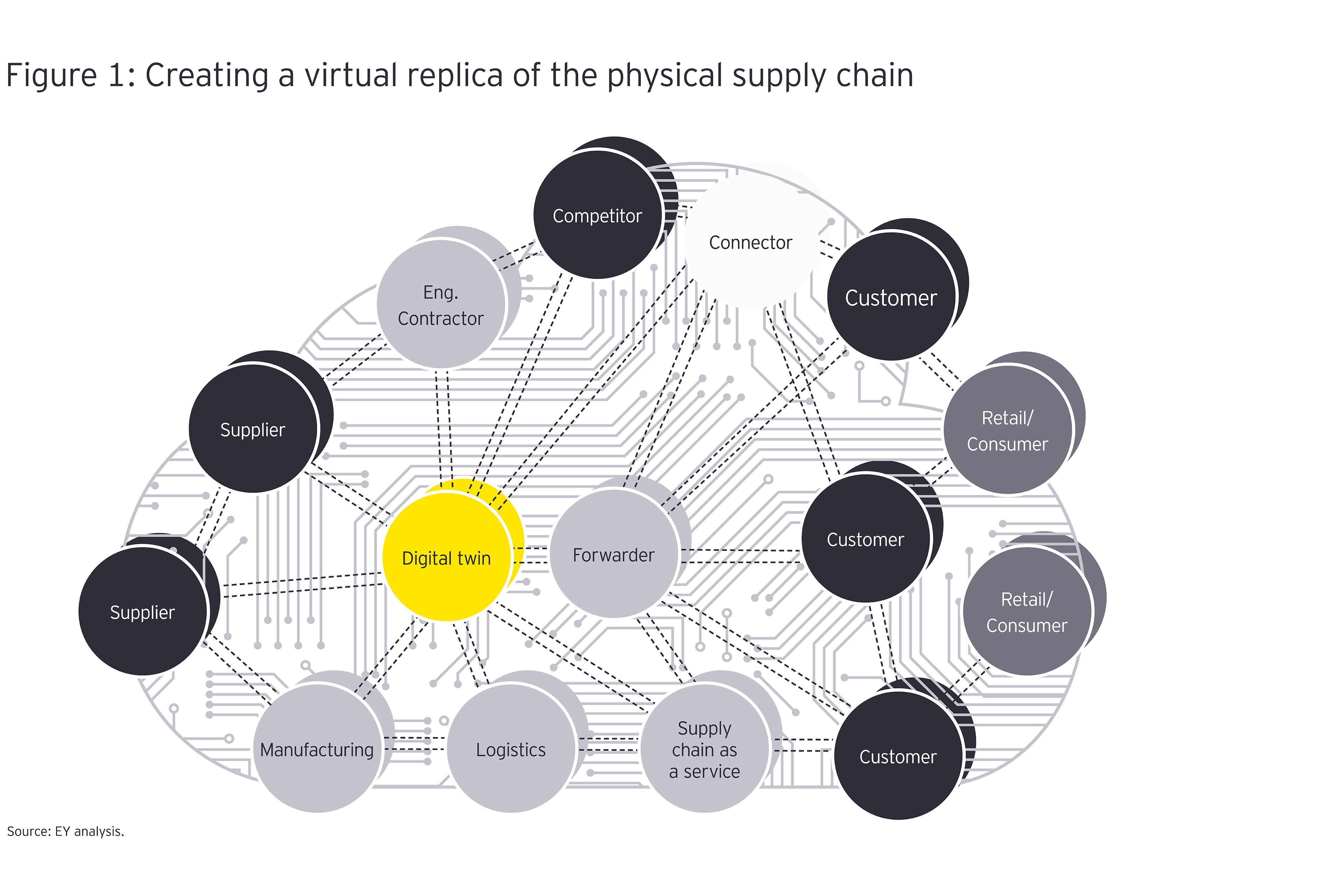

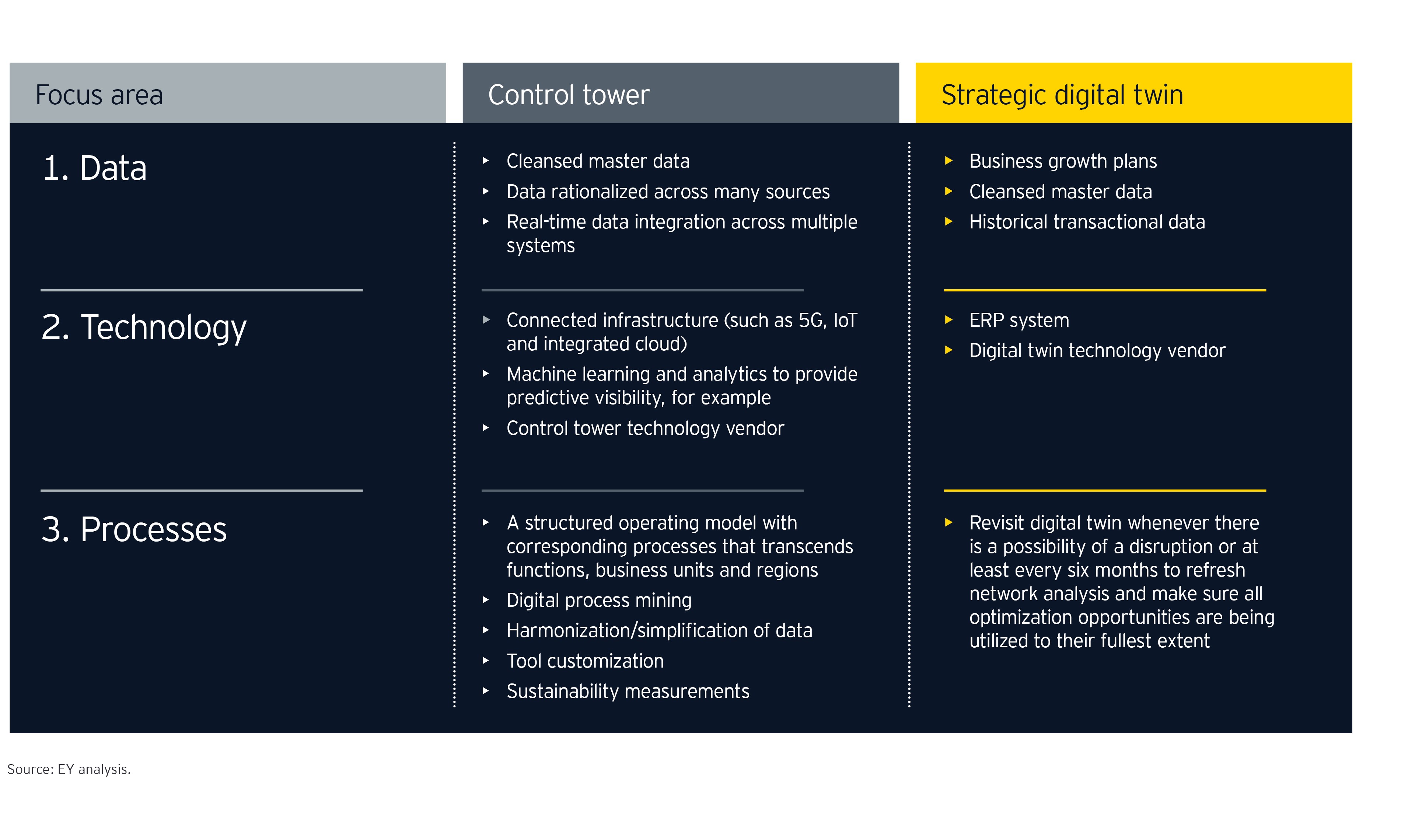

A digital twin is a bolt-on solution in most cases: a vendor provides functionality that leverages data from existing sources. But the two types (operational vs. strategic) differ significantly in the level of detail that they analyze, the immediacy of the data needed, and the type of outcomes envisioned.

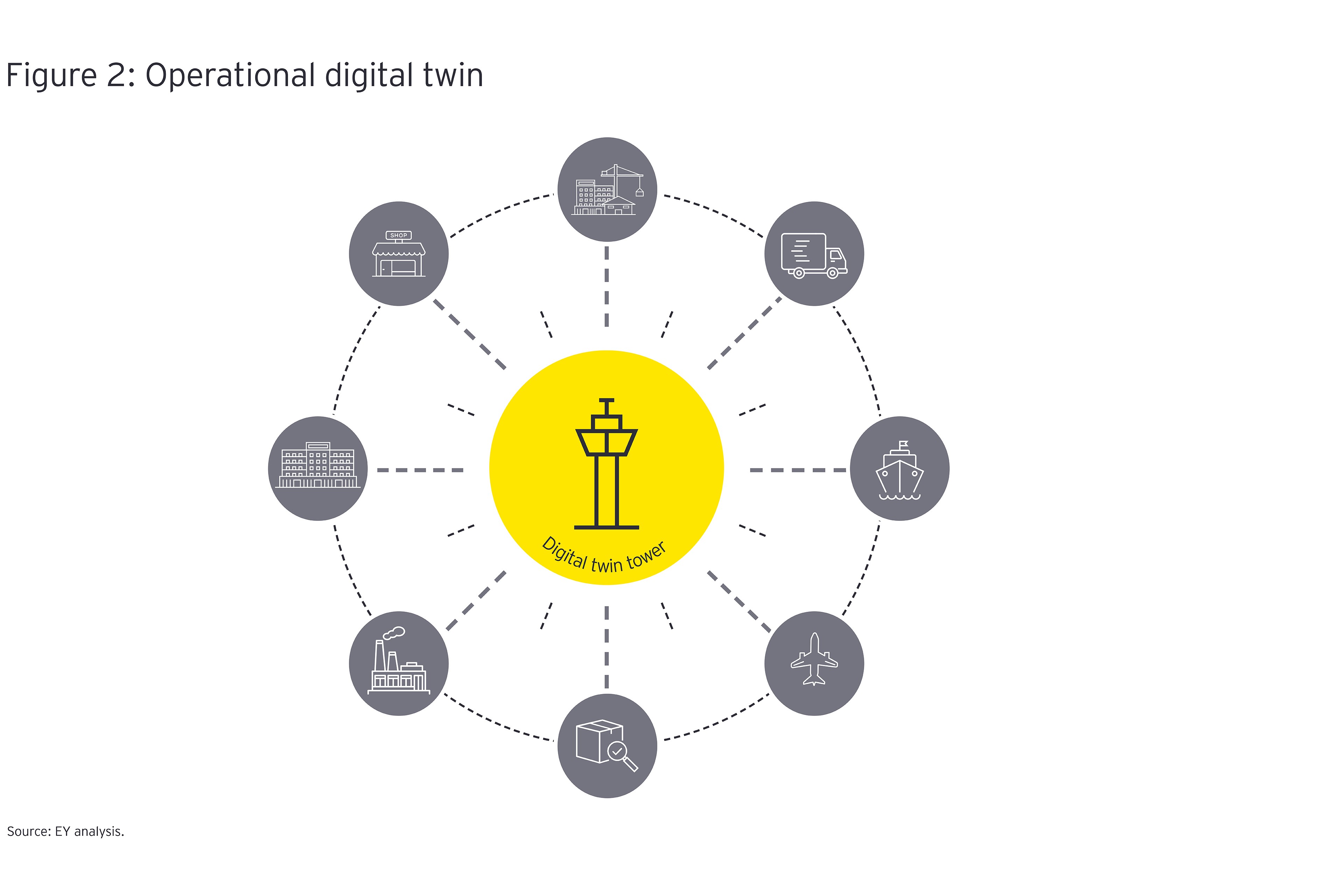

Control towers drive visibility into individual shipments and enable detailed operation-level alerts, requiring more thorough integration and a robust connectivity structure (involving technologies such as the cloud, 5G networking capabilities, IoT and GPS), and they impact more end users. Promising solutions exist on the market today for enabling controls towers, which would have been impossible just a decade ago.

By contrast, a strategic digital twin looks at the end-to-end supply chain through a more aggregated lens, involving data points concerning overall inventory, service levels, network optimization and others. These digital twins can be connected directly to an organization’s ERP system, or information could be leveraged through more manual data downloads. Currently, the solutions on the market for these digital twins are less mature and not comprehensive.

As the two digital twins are distinct, they should each be approached differently, with distinct road maps, to be future-ready.

How EY can help

Like other types of technology, digital twins also trigger a need for organizations to rethink the roles and responsibilities of human talent. The adage of today is “Technology will make things possible; talent will make them happen” — the technology is an enabler, rather than a replacer, and a manufacturer’s professionals will need to learn how to use different tools and draw on different skills.

Stakeholder analyses and engagement should be used to align on goals/KPIs for workgroups, and with those defined, an organization can better pinpoint the competencies needed to deliver. External (or in-house) tools can be used to identify gaps. Then focus resources on hiring the right talent and upskilling existing talent — for instance, through a qualifications program with rewards aligned to the business strategy. A culture of continuous learning is imperative, and external groups and alliances can be called upon for learning solutions or managed services.

These needs are similar for both control towers and strategic digital twins, although there are some differences to note. Control towers rely on a larger base of end users, at the planner/scheduler level, while strategic digital twins are more narrowly tailored to the manager level, including product, supply chain, finance, and commercial directors. Control towers also require talent that is more focused on root cause analysis and remediation, while strategic digital twins enable executive decision-making.

Conclusion

Companies face supply chain challenges today that are virtually unprecedented in modern times, and they should expect further disruption on the horizon. But while these challenges and the complexity of global operations are enormous, emerging technologies have also redefined what’s possible: delivering visibility where it has never existed before, bringing order to data that spans the globe, and replacing gut instincts and guesswork with analytics-driven insights.

Every transformation starts with an inspiration. At EY, we are creating an immersive experience where solutions like digital twins come to life, and the experience is personalized to your needs. The EY-Nottingham Spirk Innovation Hub in Cleveland, OH is where your transformation journey begins by co-creating your transformation roadmap and co-innovating with ecosystem partners.

Related article

Summary

Whether a manufacturer wants in-the-moment operational responses or long-term strategic simulations, digital twins bring together cutting-edge advances to enable flexibility and agility — competitive advantages that will grow more necessary in an ever-evolving world.